Stay Ahead of Deterioration: Essential Upkeep Tips for Undercarriage Parts

Stay Ahead of Deterioration: Essential Upkeep Tips for Undercarriage Parts

Blog Article

Vital Overview to Undercarriage Parts for Heavy Tools

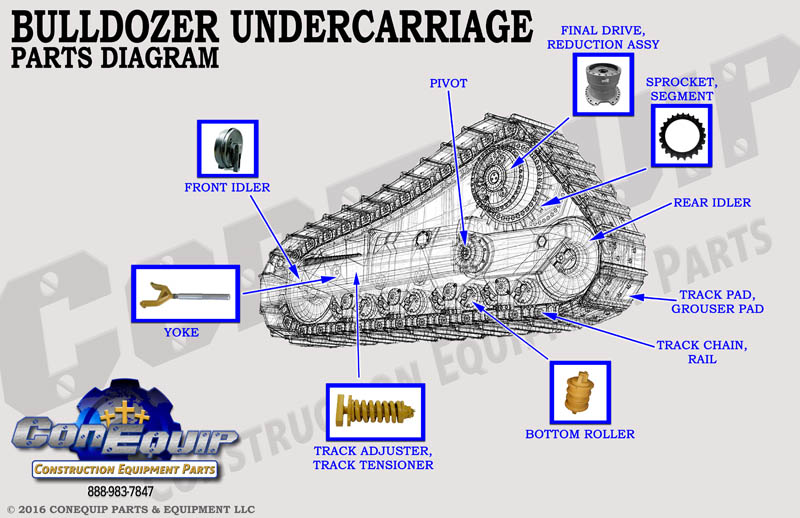

When it involves heavy tools, the undercarriage plays a critical function in ensuring reliable and smooth procedures. Understanding the intricate information of undercarriage components is vital for maximizing the life expectancy and efficiency of your machinery. From track chains to idlers and rollers, each element adds to the general capability of the equipment. Digging right into the specifics of gears and various other undercarriage components supplies vital insights into maintenance techniques that can dramatically impact the durability of your heavy machinery. By understanding the importance of these components and their maintenance requirements, drivers can maximize the efficiency and resilience of their tools, ultimately bring about cost financial savings and enhanced functional effectiveness.

Importance of Undercarriage Parts

Recognizing the vital function that undercarriage parts play in the performance and durability of heavy tools is extremely important for efficient maintenance and operation - undercarriage parts. The undercarriage components develop the foundation on which the whole device runs, supporting the weight of the devices, offering security, and taking in shock tons throughout procedure. A well-kept undercarriage not only guarantees smooth operation but also contributes dramatically to reducing downtime and repair expenses

The undercarriage consists of different vital components such as track chains, track shoes, gears, idlers, rollers, and track frameworks. The track chains and track footwear aid in providing grip and assistance, while the gears and idlers assist in driving the tracks smoothly.

Kinds of Track Chains

Track chains are crucial components of hefty tools undercarriages, supplying the essential grip and support for efficient operation. There are largely 2 kinds of track chains made use of in hefty devices: sealed and lubricated track chains (SALT) and completely dry track chains. Sealed and oiled track chains are commonly discovered in contemporary hefty machinery. These chains are pre-lubricated and secured to avoid dust, debris, and moisture from entering the chain joints, making certain smooth procedure and extending the chain's life expectancy. On the other hand, completely dry track chains need regular hands-on lubrication to preserve optimum efficiency and stop early wear.

Duty of Rollers and Idlers

Rollers and idlers play a critical duty in supporting and guiding the track chains of hefty equipment undercarriages, contributing to the total security and effectiveness of the machinery. Rollers are created to support the weight of the equipment and supply a smooth surface for the track chain to move along. They assist disperse the weight equally, lowering too much endure the track chain look these up and making certain appropriate grip. Idlers, on the other hand, overview the track chain and help preserve correct stress throughout the undercarriage system. By guiding the track chain in a regulated fashion, idlers stop extreme side-to-side motion, decreasing the threat of derailment and uneven wear.

Together, idlers and rollers function in harmony to guarantee that the track chain stays in area, also on harsh surface, improving the devices's performance and durability. Proper maintenance and normal inspection of rollers and idlers are important to avoid early wear and prospective breakdowns, eventually maximizing the performance and lifespan of heavy tools undercarriages.

Comprehending Gears

One critical facet of sprockets is ensuring appropriate positioning and tension to avoid early wear and damage. Misaligned sprockets can create uneven wear on the track chain, bring about reduced performance and prospective safety risks. Normal upkeep and have a peek at this website inspection of gears are important to determine any type of indications of wear or imbalance promptly.

Additionally, sprockets can be found in various dimensions and tooth arrangements, depending on the particular hefty devices and its desired usage. Proper option of gears based upon the tools's requirements is crucial to make sure optimum performance and longevity of the undercarriage system. Recognizing the role of sprockets and their upkeep needs is crucial for taking full advantage of the effectiveness and life-span of heavy tools undercarriages.

Upkeep Tips for Durability

To ensure the prolonged resilience and optimum functionality of heavy equipment undercarriages, attentive maintenance methods are important. Regularly inspecting undercarriage parts such as track footwear, rollers, idlers, and gears for wear and tear is critical. Correct track stress adjustment is additionally crucial for reducing premature wear on undercarriage components.

Conclusion

Finally, undercarriage components are vital parts for heavy tools, playing important functions in preserving security and functionality. Understanding the various kinds of track chains, rollers, gears, and idlers is essential for proper upkeep and durability of the devices. By complying with upkeep pointers and consistently evaluating and replacing worn components, drivers can make certain the optimum efficiency and efficiency of their heavy equipment. Correct care and interest to undercarriage parts are crucial to maximizing equipment lifespan and performance.

The undercarriage consists of numerous necessary parts such as track chains, track footwear, sprockets, idlers, rollers, and track frames. The track chains and track footwear assist in supplying traction and support, while the sprockets and idlers help in driving the tracks smoothly (undercarriage parts). There are mainly two types of track chains utilized in heavy tools: secured and over here oiled track chains (SALT) and completely dry track chains. Appropriate option and upkeep of track chains are essential to guarantee the overall efficiency and durability of heavy equipment undercarriages

Gears are important components of hefty devices undercarriages, accountable for transferring power from the equipment to the track chain.

Report this page